Associate Professor Sakaino declared during his job interview at the University of Tsukuba that “At least before I retire, I will eliminate physical labor performed by humans”. With this vision in mind, he has been advancing research on and the development of robots by integrating bilateral control with artificial intelligence (AI). Bilateral control, a core technology he has pursued since his graduate school days, serves as the foundation of this work.

Robots Exchanging Not Only Movements, but Also Tactile Sensations at a Distance

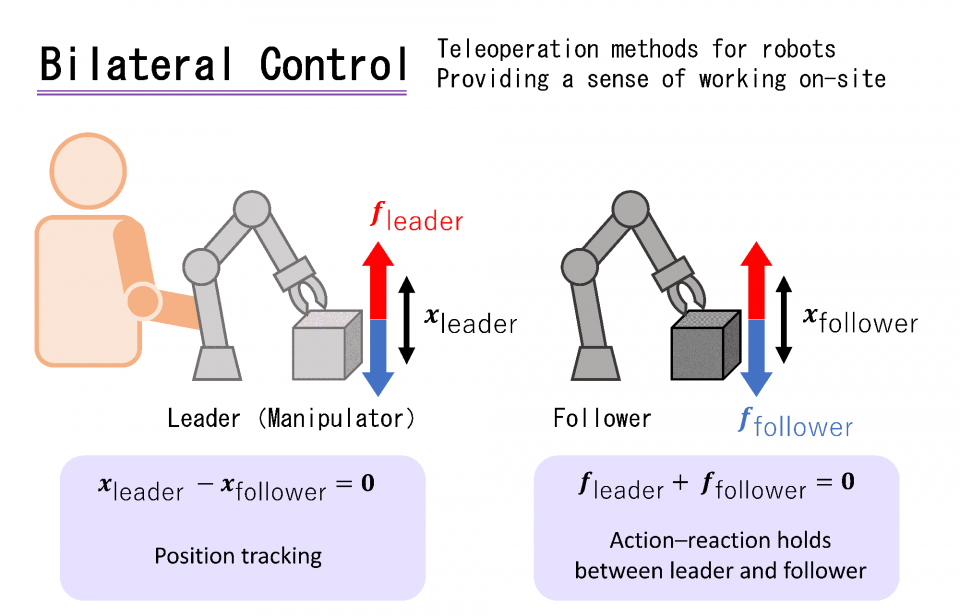

By applying bilateral control, it becomes possible for two robots placed far apart to exchange not only their movements, but also their tactile sensations. In the case of surgical robots, the tactile sensations and movements of the leader robot, which is operated and commanded by the surgeon, are synchronized with those of the follower robot, which directly performs the surgical procedure by manipulating various instruments, such as scalpels. This mechanism enables remote surgery to be performed safely (Figure 1).

However, bilateral control has rarely been applied outside of specialized fields, such as medicine and space exploration. Since two robots are required, its implementation is difficult in areas where significant financial investment cannot be justified. Nevertheless, I have continued working with this technology, convinced of its broader applications. The door that opened new possibilities has been AI.

Figure 1. Bilateral Control (Provided by the Motion Control Laboratory [Sakaino], University of Tsukuba)

Teaching AI Robots Force Modulation Through Bilateral Control

In 2016, I observed a student presentation on AI robotics that demonstrated how image recognition enables a robot to grasp objects it had never encountered before. However, the robot’s grasping was clumsy and objects frequently slipped from its hands. At that moment, I realized that the control of hand movements and the modulation of tactile force, namely, the adjustment of grip strength, are both essential. By applying bilateral control, AI robots may be trained to learn not only motion, but also the appropriate amount of force.

Humans naturally hold objects, such as teacups or files, through learned behavior from infancy on how to modulate force through repeated interactions with a wide variety of objects. Force adjustment is also essential when performing various tasks using tools, such as kitchen knives. By first allowing humans to recognize the necessary force and motion and then transferring this knowledge to AI robots via bilateral control, robots may acquire these skills quickly and efficiently.

Examining the “Essence of Intelligence” Through the Development of Household Robots

Currently, my greatest aspiration is to realize the “household robot”. This robot will skillfully manipulate a variety of tools with precise force adjustments to perform cooking, cleaning, laundry, and other chores. Unlike conventional industrial robots, which execute a single task with extreme accuracy and speed, the household robot is envisioned to handle a wide range of tasks with moderate accuracy and speed in a similar manner to humans. This domain has remained largely unexplored, and I aim to pioneer it through the integration of bilateral control and AI.

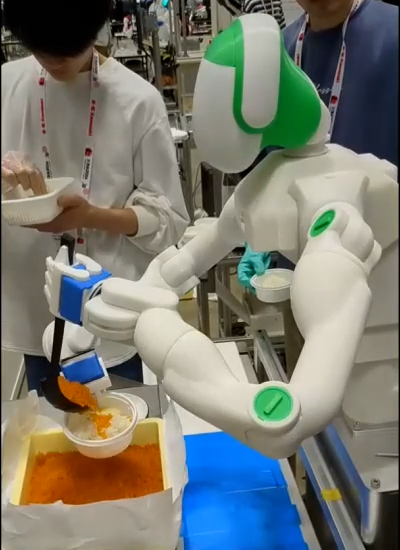

As one step towards this goal, we participated in the “Food Topping Challenge” in May 2024 at the IEEE RAS international conference ICRA 2024 in Yokohama, where we won first place. In this event, an existing robot was trained to learn the sequence of movements and force adjustments required to lift a bowl from the table with its right hand, scoop salmon roe with a ladle in its left hand, place the roe into the bowl, and return the bowl to the table. The process was executed smoothly (Figure 2). Experts in AI robotics were surprised because only two days before the competition, we updated the command data on-site by having a human demonstrate the task through bilateral control. In contrast, conventional AI robot training typically involves collecting data over weeks or months, training AI with these data, and bringing carefully preprogrammed command data to the venue.

Figure 2. The robot that won the “Food Topping Challenge”

(Provided by Motion Control Laboratory [Sakaino], University of Tsukuba)

Source: https://arxiv.org/pdf/2504.19498

Video: https://x.com/shosakaino/status/1791030970914914566

The generation of even a single motion for a robot generally takes between six months and one year, with enormous associated costs. However, with the technology developed by us, it will become possible to implement an AI robot under controlled factory conditions that has the ability to switch from using a ladle to different tools, such as tongs or forks, and perform the plating of various dishes, including hamburg steaks and salads, within one year.

By advancing research and development in this manner, where AI robots progressively take over household labor, the fundamental question of “What is intelligence?” is one step closer to being addressed.

(Date of interview: June 31, 2025)